It’s science time. New research tells us how, with the help of metalenses and spaceplates, we don’t need conventional lenses anymore. Furthermore, that will allow manufacturers to develop tiny cameras with bigger sensors. Read the highlights of the research below.

The solution for reducing the size of lenses (and cameras)

New research has found a solution for reducing the size of cameras, by combining both metalenses and spaceplates. That combination allows a significant reduction of the glass and the length from the camera sensor. The result can be a lens-free camera and a bigger sensor. Furthermore, it’s a whole new approach for how light can be focused, and utilized, that can result in manufacturing facilitation of both cameras and lenses.

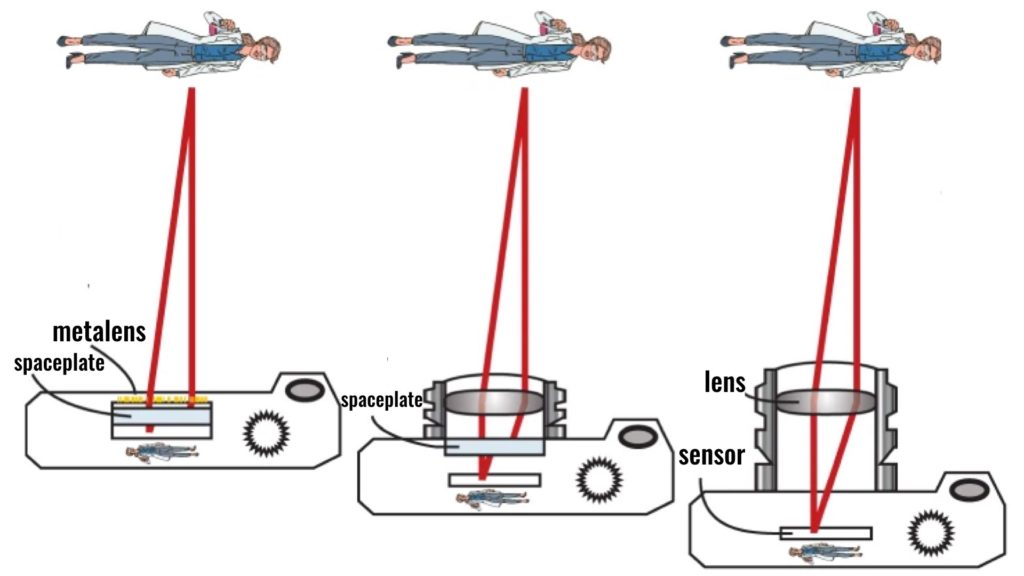

Adding a spaceplate to an imaging system such as a standard camera will shorten the camera. An ultra-thin monolithic imaging system can be formed by integrating a metalens and a spaceplate directly on a sensor.

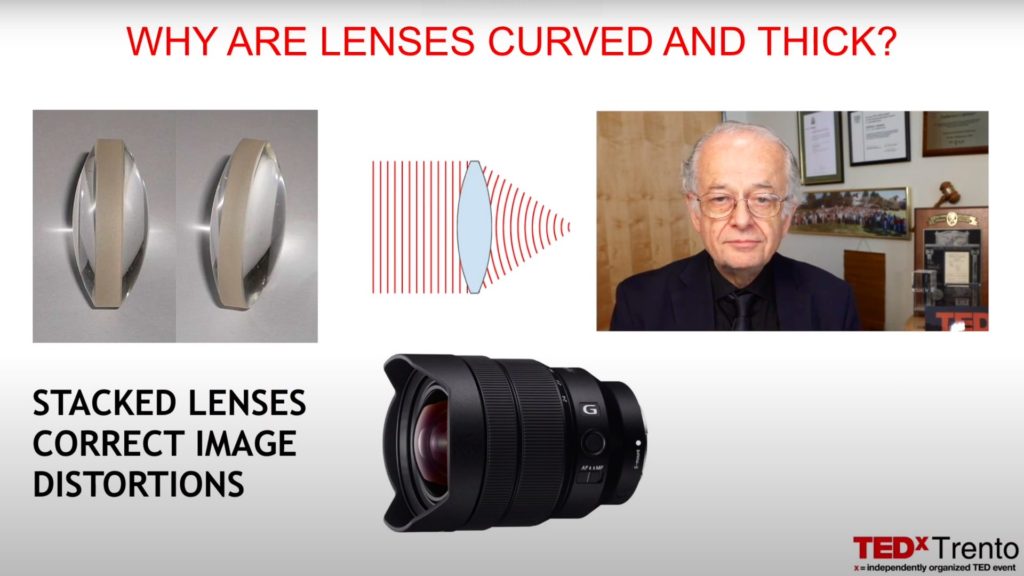

What are metalenses?

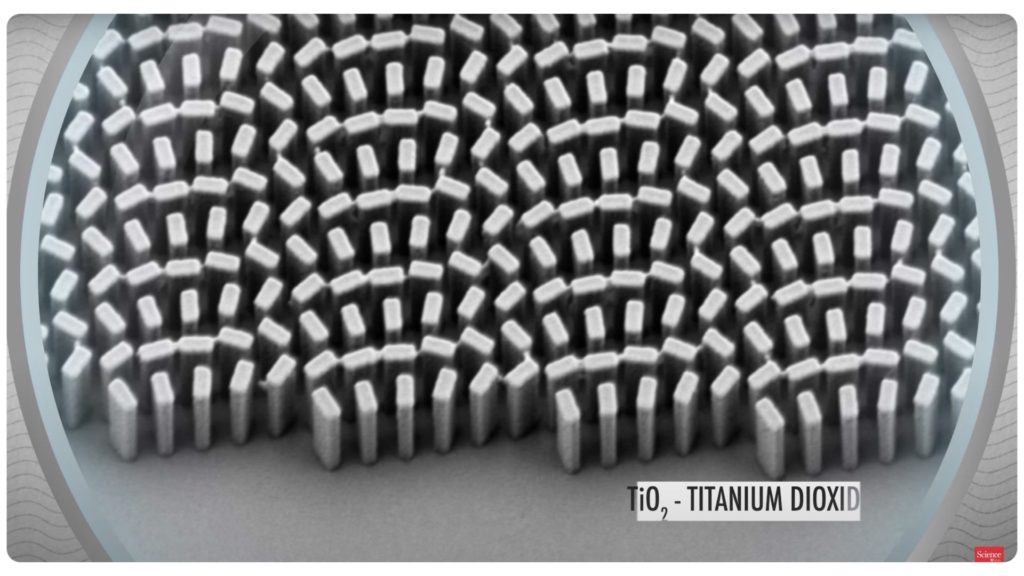

Metalenses are known for some time. The metalenses are characterized by their metasurface, which is tiny towers of titanium dioxide that are arranged in a specific pattern to focus light. Different patterns focus on different colors of light. In a traditional lens, the glass varies in thickness between the middle and edges. Inside the lens, the wavefront of light is shaped via different thicknesses of glass. This focuses the light at one specific point beyond the lens. However, in the metasurface lens, the transparent blocks also bend the light toward the focal point, matching what happens in the glass lens but with much less material (600 nanometers in length can achieve the same resolution and magnification as a lens that is 5 to 6 centimeters in length). Furthermore, the fabrication of these metal lenses should also be much more cost-effective compatible with silicon chip technology, versus complex polishing and sometimes stringent requirements for high-performance lenses. Eventually, with flat lenses, the thickness, size, and cost of lenses will be dramatically reduced and the image sharpness greatly improved.

Check out the video below for a simplified explanation:

And if you’d like to dive a bit deeper, explore this TED Talk below which further demonstrates this revolutionary approach.

Spaceplates

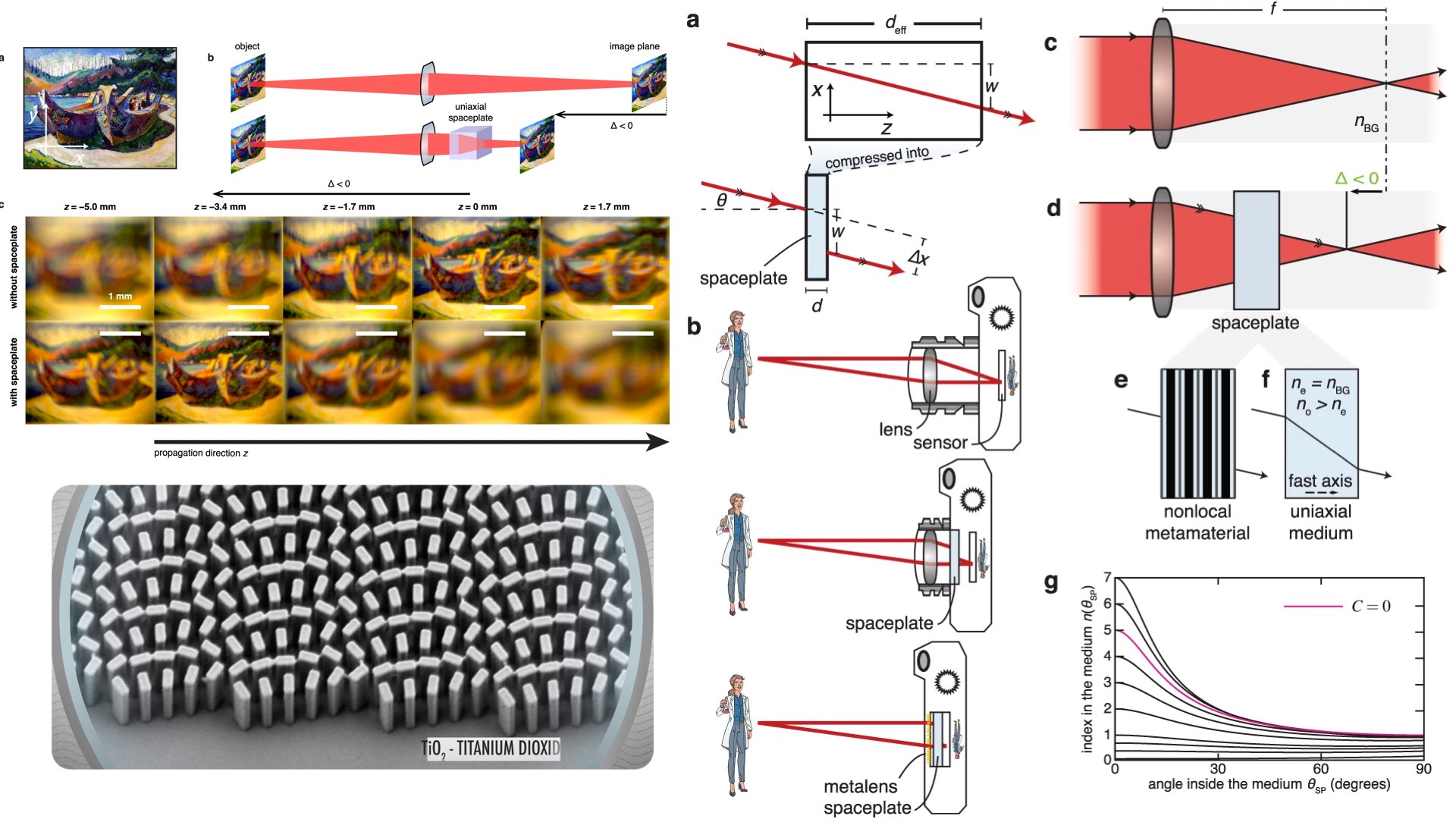

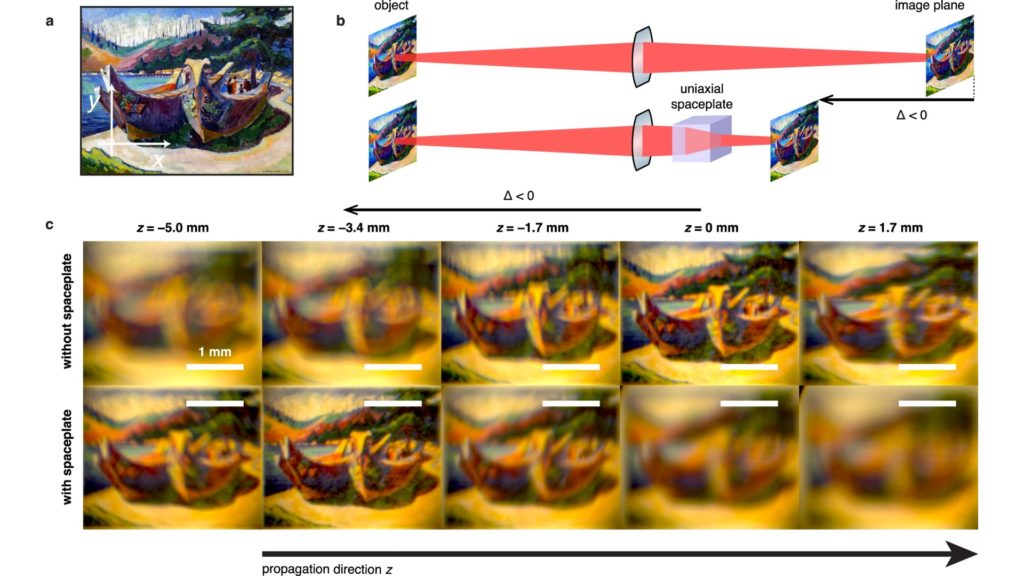

However, unaddressed by this promise is the space between the lenses, which is crucial for image formation but takes up by far the most room in imaging systems. In am article published by the Département de Physique et d’Astronomie, Université de Moncton, with the Department of Physics, University of Ottawa, School of Electrical Engineering and Computer Science, University of Ottawa, and Institute of Optics and Department of Physics and Astronomy, University of Rochester, the researchers tried to address this issue by presenting the concept of and experimentally demonstrating an optical ‘spaceplate’, which is an optic that effectively propagates light for a distance that can be considerably longer than the plate thickness. The research claims, that such an optic would shrink future imaging systems, opening the possibility for ultra-thin monolithic cameras.

Spaceplates + metalenses = Enhanced efficiency

According to the research, adding a spaceplate to an imaging system such as a standard camera will shorten the camera. An ultra-thin monolithic imaging system can be formed by integrating a metalens and a spaceplate directly on a sensor. Explore the slide below that demonstrates that hypothesis:

Positive side effect: Utilization of bigger sensors

As stated in the research: “The space between the lens and the sensor of a camera is dictated to a large degree by the focal length f of the lens. A relatively large focal length is necessary to suitably magnify an image, which leads to long lens barrels in cameras. One approach toward reducing this length could be the use of a spaceplate, allowing for the large magnification of a faraway object without the need for a large propagation length”. Moreover, according to the research, since the resulting image may now be large, so can the image sensor: “One can capitalize on this larger sensor by using larger pixels for low-light sensitivity, or a greater number of pixels for a higher resolution. In this way, the spaceplate could one day break the trade-off between camera miniaturization and any of resolution, sensitivity, magnification, or field-of-view”. That means, larger sensors can be implemented on much smaller cameras.

In this way, the spaceplate could one day break the trade-off between camera miniaturization and any of resolution, sensitivity, magnification, or field-of-view.

Summary

Is this the future of imaging systems? It’s hard to conclude that, for now, since the filmmaking and photography industries are very technological, but conservative as well. It’s a long shot though. Manufacturing a large sensor lens-free camera that will be able to shoot professional images it’s a challenge. However, meta-surfaces are the future, and it’s quite possible that will be implemented and utilized in professional cameras as well. Don’t you think? Feel free to comment.

Source: An optic to replace space and its application towards ultra-thin imaging systems