A startup company, named CURVE, has developed the first commercial curved CMOS sensor. Would it be defined as a new era in optical vision? It might, as curved sensors own some valid advantages. Read more about curved sensors and how they can contribute to the film industry.

The first public image of Sony’s curved CMOS sensor. Source: Image Sensors World (from 2014)

Full frame curved sensor: Sony was the first

The sensors inside digital cameras are flat. But curved sensors promise greater sensitivity, better image quality, and open possibilities scope for simpler lenses. The curved sensor mimics the design of the retina in the human eye, which results in a simpler lens system that is 1.4x more sensitive at the center and 2x more sensitive at the edges and thus boosting sensitivity. Sony was the first to design full-frame curved sensor technology back in 2014. As for the lens, because of the geometry, curved sensors can be paired with a flatter lens and a larger aperture. The photodiodes at the periphery of a sensor array will be bent toward the center, which means light rays will hit them straight on instead of obliquely.

By directly correcting the field curvature in the focal plane of imagers, the use of curved sensors suppresses the field flatteners. Thereby it improves image acquisition quality.

The first commercial curved CMOS sensor

The first public studies in the field of curved sensors are back in the 2000s, but no commercial product has launched. However, a startup company named CURVE, supported by the European Commission through the European Research Council programs, made it become an available product. Let’s read the explanation in the press release: “The advent of flat electronic sensors has been a revolution, forcing optical designers to introduce additional optics to fit the flatness of these sensors’ surface. The classical problem of the planisphere appeared then: a huge distortion is created by the imaging system on the edge of the field. Additional complexity came along with the distortion: field flatteners increase the volume and mass of systems, and chromatic aberrations appear. Also, the imaging response is not uniform across the field. The development of curved sensors is a bio-inspired approach. Mimicking the eye retina, this new technology impacts every future imaging system. By directly correcting the field curvature in the focal plane of imagers, the use of curved sensors suppresses the field flatteners. Less optics means less misalignments and instrumental errors, increases the stability and image homogeneity and reduces the dependence to environmental condition. Thereby it improves image acquisition quality and then reduces image post-processing costs”.

Explore the document below (French and English):

[pdf-embedder url=”https://ymcinema.com/wp-content/uploads/2020/12/CP_AMU_CNRS_CURVE_CapteurCourbe.pdf”]

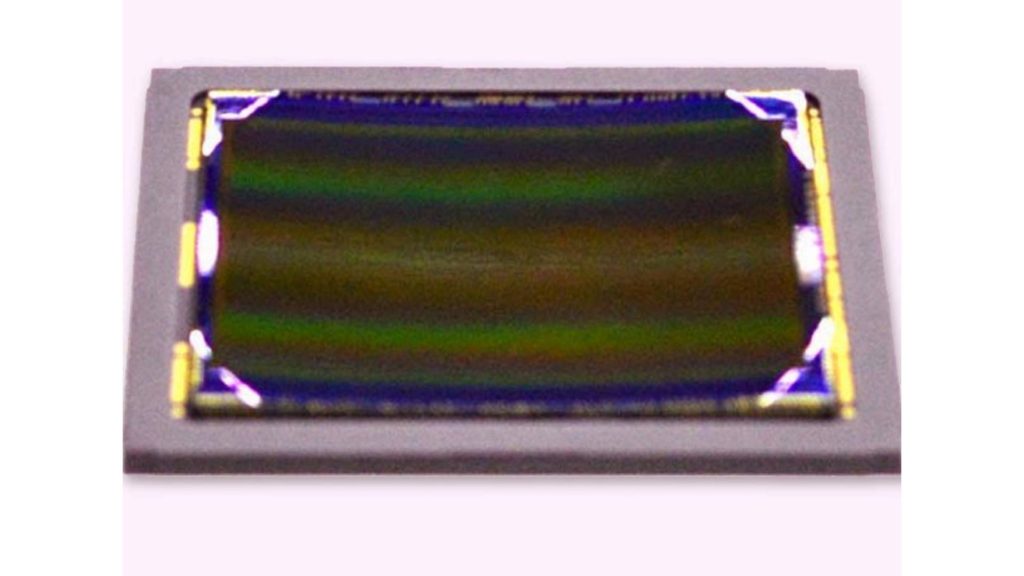

Getting ready for mass production

CURVE is now targeting the mass production of its curved sensor, with the support of the European Commission as well as the support of the European Space Agency. Explore the sensor itself in the picture below.

Summary

This first commercial curved CMOS sensor is indeed a breakthrough regarding imagery techniques and methods. Nevertheless, it will take some time to be implemented in our industry. However, don’t be surprised if Sony, Canon, and more camera manufacturers that have high production capabilities regarding their sensor development, will announce a curved sensors apparatus implemented on their future cameras. Of course, this will be accompanied by dedicated lenses. Head over to the company’s website to see a demonstration of this curved sensor.

You got your CURVE backward in the diagram. The curve should be convex toward the incoming light rays, not concave. A concave curve makes incident light angles from the edges worse, not better.

You’re right, and we thought just that as well. However, we had to paste the scheme as-is from the publication.

You misspelled the company name as CRUVE in the very first sentence of the article

Corrected. Thank you!

Hi, It’s interesting. Would it possible to see the actual difference(improvement) in the actual photos?

Hi Javier,

Check their website https://www.curve-one.com/optical-design-fisheye-curve-one80/ for a demonstration.

Let’s hope to see it implemented inside a consumer camera in the very near future.

Thx,

Yossy