Canon has officially entered a new phase in its camera and lens production strategy — and it’s one that could reshape the industry. In its 2024 Annual Report, Canon subtly dropped a bombshell: the rollout of automated production lines for both cameras and interchangeable lenses. This development may sound like an operational detail, but it carries massive implications for Canon’s market position, competitive edge, and the future of imaging technology.

From Toner to Glass: A Shift in Scale

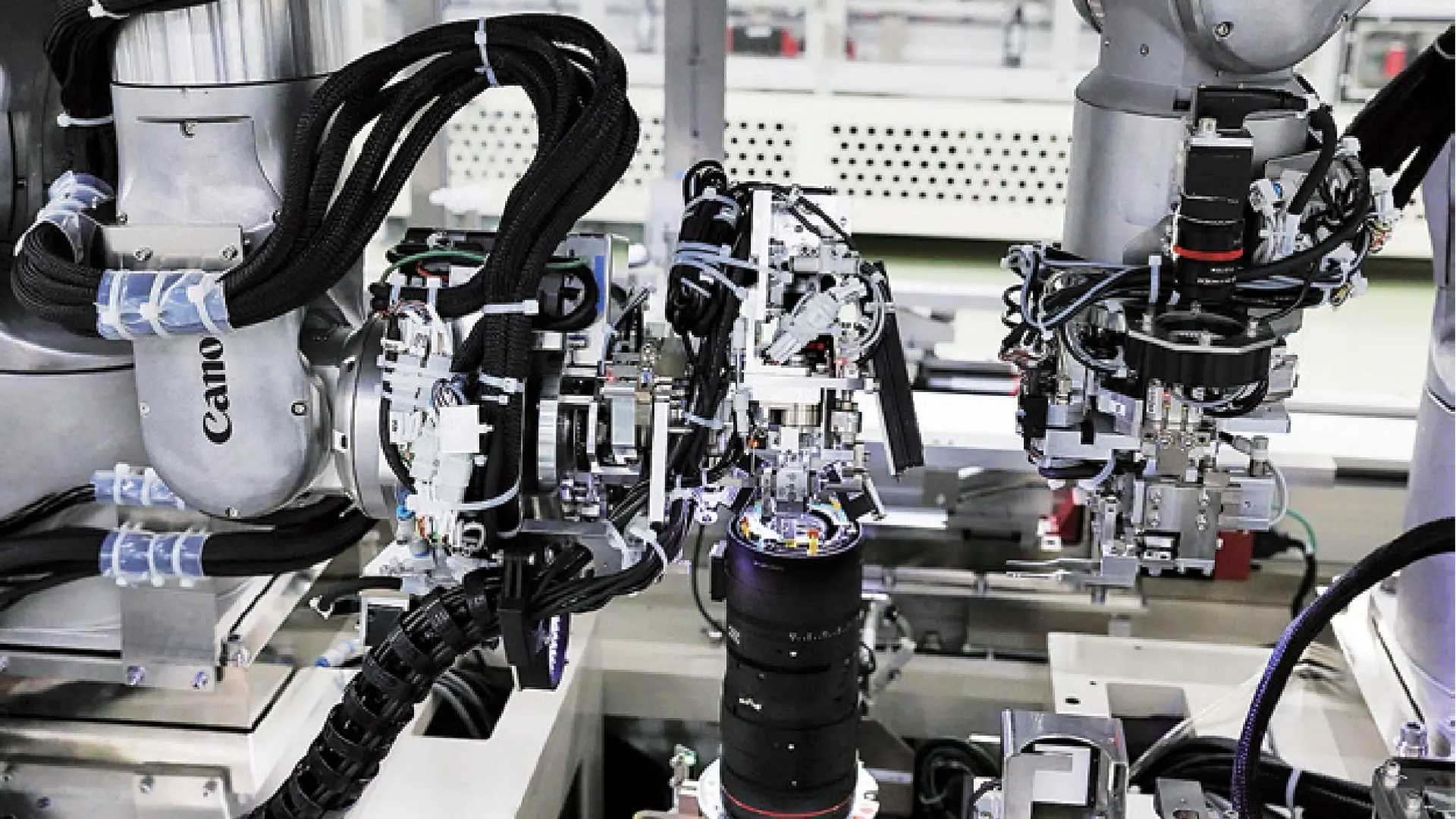

Canon has long been known for its vertically integrated manufacturing — making everything from sensors to lenses to processors in-house. But automation of complex precision products like RF-mount lenses and mirrorless camera bodies is an entirely different feat compared to toner cartridges.

Following toner cartridges, we have rolled out automated production lines for cameras and interchangeable lenses to further enhance productivity.

Canon Inc., Annual Report 2024

In essence, Canon is scaling a system that was once designed for mass office equipment to now handle the delicate tolerances of high-end optical gear. This is no small pivot. It signals a long-term strategy to reduce human labor, increase consistency, and enable rapid scaling of next-generation imaging products. Here’s Canon’s full statement: “Canon aims to achieve further production efficiency by leveraging technologies cultivated in different businesses regardless of divisions and by collaboration among design, production engineering, and manufacturing sites, to refine its automation and in-house production technologies. In addition to key devices and components, we are also actively pursuing in-house production of production equipment and molding dies. Following toner cartridges, we have rolled out automated production lines for cameras and interchangeable lenses to further enhance productivity”.

Automation + In-House Everything

What makes this move even more powerful is Canon’s commitment to in-house production not just of parts — but of the production equipment itself. Canon states that it is “actively pursuing in-house production of production equipment and molding dies,” meaning it is eliminating dependence on third-party machinery manufacturers. This level of integration is rare, even among global giants. It gives Canon:

-

Ultimate control over quality

-

The ability to iterate and innovate faster

-

A hedge against supply chain disruptions

- Fighting against Trump’s tariffs

Cross-Divisional Technology Transfer

Canon is also leveraging technology from different divisions to supercharge its imaging business. That means robotics and automation developed for printers or industrial products are being adapted for camera assembly. This cross-pollination of tech isn’t just smart — it’s essential. As competitors like Sony continue to push innovation in AI image processing and sensor design, Canon’s bet is that tight internal coordination and streamlined production will allow it to keep pace without bloated R&D or outsourced manufacturing complexity.

Cost Efficiency = Competitive Advantage

As the camera market gets increasingly competitive — especially in the mirrorless space — Canon’s automation initiative is likely aimed at:

-

Reducing production costs

-

Stabilizing retail pricing

-

Preserving margins in an era where consumer demand fluctuates and unit volumes are challenged

If Canon can produce the EOS R1 or R5 Mark II with greater efficiency and consistency, it can undercut rivals, offer more compelling bundles, and maintain dominance in the shrinking but fiercely loyal enthusiast and professional segments.

What This Means for Filmmakers and Cinematographers

The implications go beyond just pricing or availability. Automated production could:

-

Improve consistency in optical quality between lens batches — a known issue with mass-produced lenses.

-

Enable faster delivery of new cinema lenses, RF glass, and bodies tailored for video professionals.

-

Set a new standard for what reliability and tolerances filmmakers can expect — even at mid-range price points.

In short, this isn’t just about robots building cameras. It’s about reshaping the way gear is conceived, produced, and delivered — with implications that ripple across the production pipeline.

Final Thoughts: A Strategic Masterstroke?

Canon’s quiet shift toward automation may be its boldest strategic move since abandoning the DSLR flagship and committing fully to mirrorless. It’s not just a manufacturing upgrade — it’s a technological positioning statement. At a time when AI, supply chain instability, and rising costs are redefining hardware development, Canon is doubling down on control, speed, and precision. While Sony continues to innovate at the chip level, Canon is reminding the industry that how you build a camera is just as important as what it does.