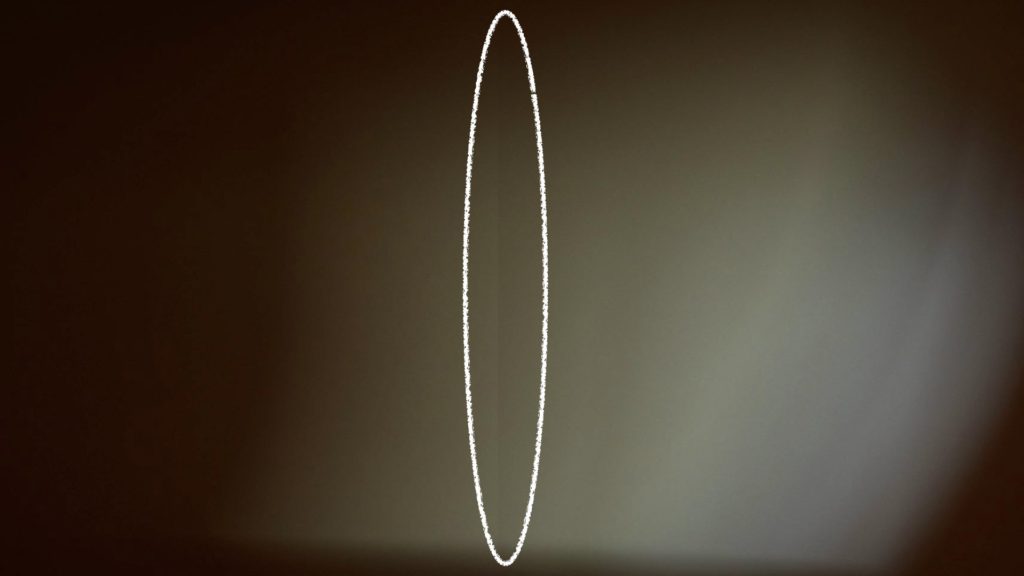

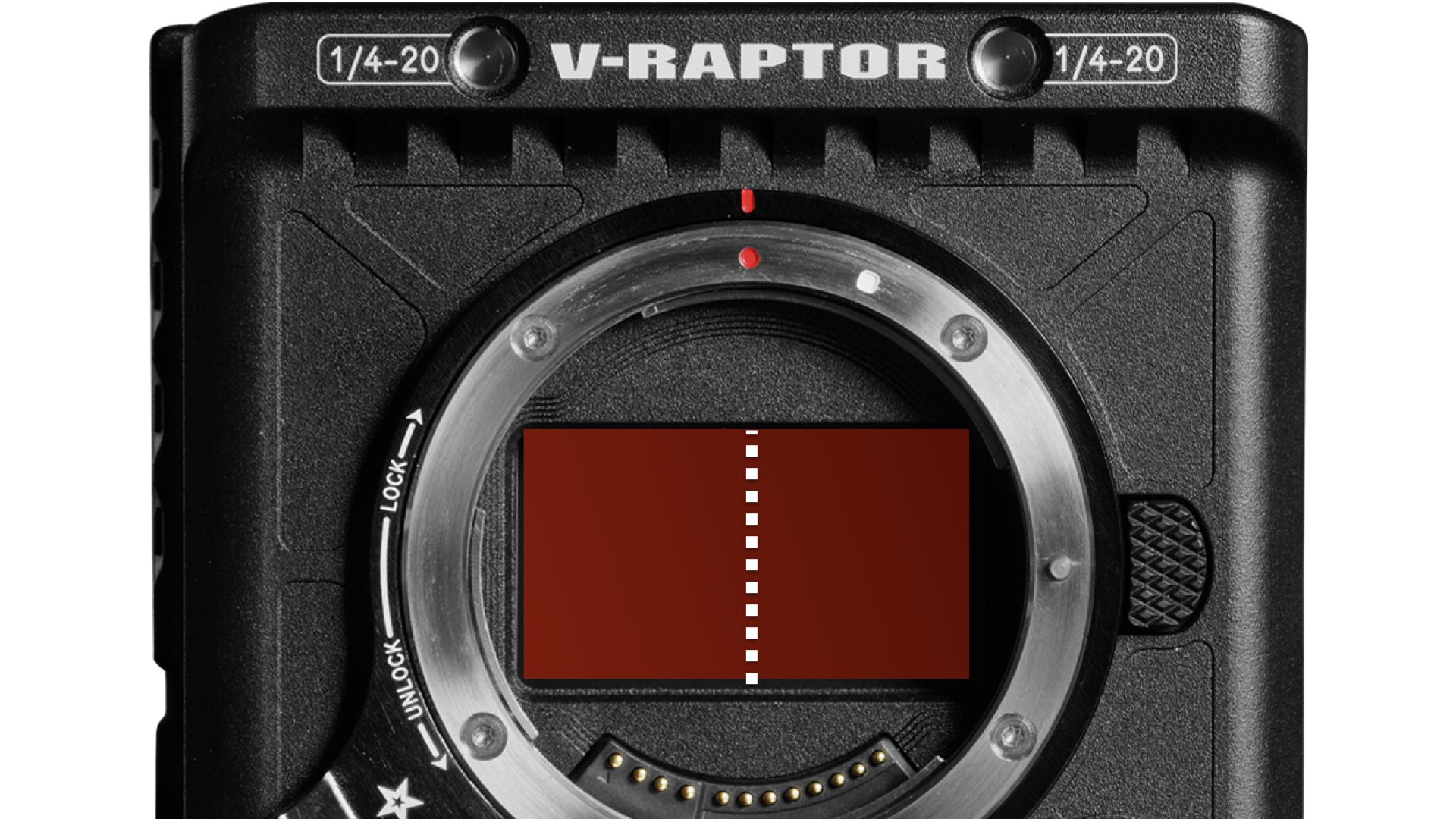

RED V-Raptor shooters revealed unwanted artifacts of a line from top to bottom that appeared in their footage. It gave the impression that this line is the split of the stitched sensors of the camera. RED has confirmed that its Vista Vision sensors are designed of two sensors stitched together. Furthermore, RED has confirmed that the artifact is derived from the split of the stitched sensors. Although this artifact is considered ‘normal’ in large format sensors, RED has decided to investigate that phenomenon.

A mysterious line/artifact was seen in RED V-Raptor footage

Some RED V-Raptor shooters have noticed a strange artifact on their footage. The artifact is a line from top to bottom. It’s important to note that it’s not so easy to replicate this artifact, since it appears under a very specific shooting environment combining certain angles of light, ISO, and more parameters. Eventually, RED has approved that this line is a result of the stitched sensors. RED confirmed that its large sensors (DSMC2 VV, and DSMC3 Raptor) are basically two sensors that are stitched together, and this line presents the split of the stitching.

RED V-Raptor sensor stitch issue: Vimeo reference

The clip below exhibits the sensor stitching line down the center of the frame. The clip was shot by Brandon Peterson. “I’ve shot a lot of footage on my V-Raptor already, much of it shooting into the sun because I love flares, and this is the only time I’ve seen this issue” stated Brandon. The clip was shot with Schneider 4 x 5.65″ Hollywood Black Magic 1/8 Filter (HBM 1/8) and Angenieux EZ-2 at 60mm FF at T3. ISO 800. “It was shot all morning in those lighting conditions and this was the only time I could see the issue” he added. Explore the clip below: Downloading is enabled. Brandon has uploaded it in ProRes 8K.

You can also download the RAW files via Dropbox.

Sources and links to discussions

- Here’s the link to the FB post which raised some hot discussion among RED users.

- Furthermore, explore the links to the discussions on the REDUser forum:

Monstro and Raptor sensors are manufactured by aligning two sensors side-by-side

This is RED’s answer after examining the clip’s log file: ”Thank you for providing the camera log file and an image sample. As is common with large format sensors in our industry, the RED V-RAPTOR 8K VV sensor is manufactured by aligning two sensors side-by-side to create one larger sensor. In rare situations, it is possible to notice the seam between the left and right halves of the image, however, it should not be visible under normal shooting conditions”. (link to source).

As is common with large format sensors in our industry, the RED V-RAPTOR 8K VV sensor is manufactured by aligning two sensors side-by-side to create one larger sensor. In rare situations, it is possible to notice the seam between the left and right halves of the image, however, it should not be visible under normal shooting conditions.

RED Digital Cinema

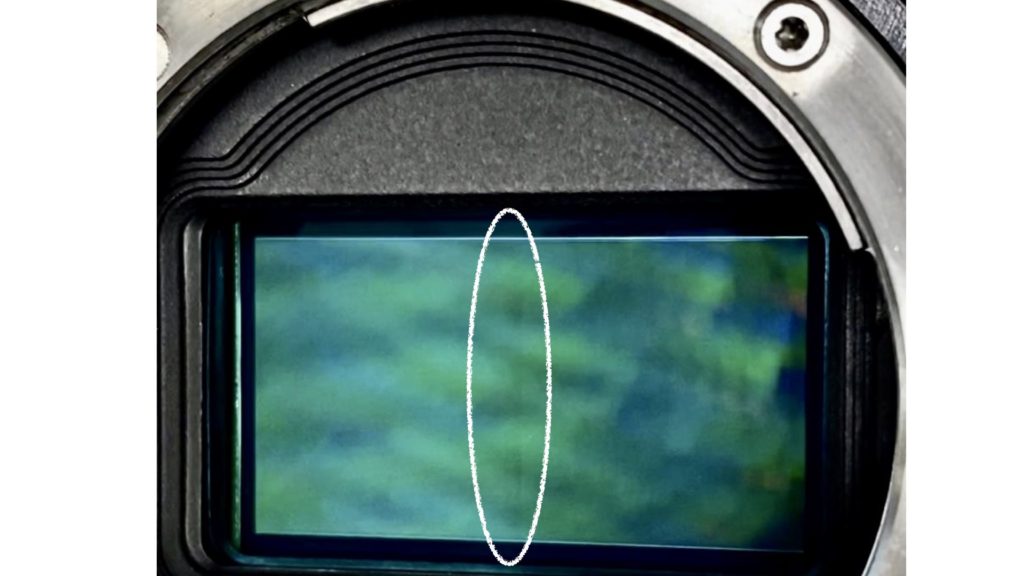

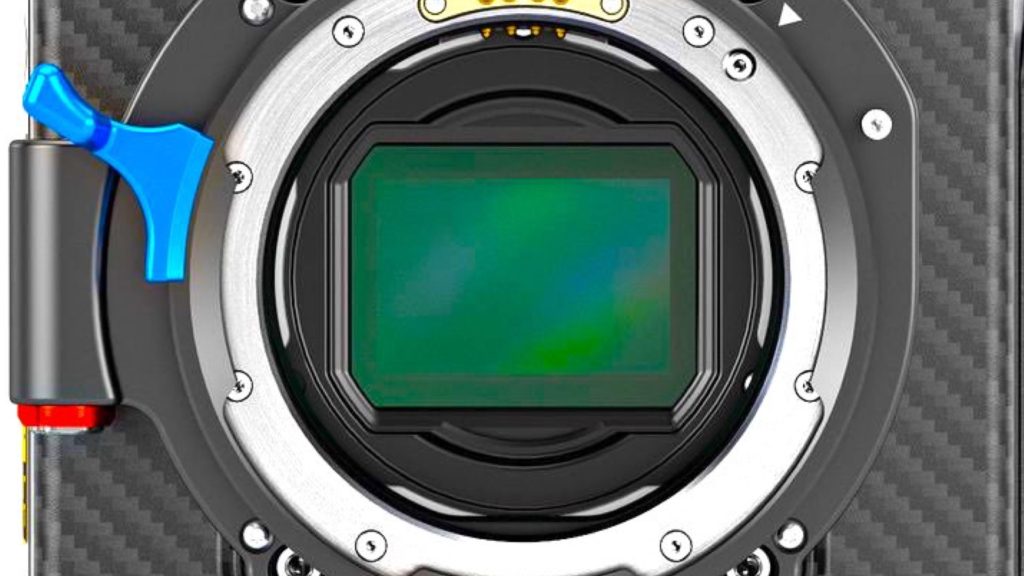

The split is shown on RED Monstro sensor

On another evidence revealed by REDUser Daniel Bichler, as stated: “I took a picture of the V-Raptor sensor today. It definitely has a line in the middle but is very difficult to photograph. I was defined very surprisedly…Then I’ve checked my beloved Monstro and found the same line on its sensor. Not as strong as on Raptor but it’s there! Never had issues on Monstro, though”. Explore the picture below which shows a delicate line on the Monstro sensor. There’s a probability that this line represents the stitching point between the two sensors.

FB user Charles Bergquist adds: “Here are some more samples of the issue with a lens on. I needed to send these to Red Engineering so they can assess the problem. Basically, anything backlit you need to be incredibly careful if it’s a project that is important and cannot be reshot”. (Link to source).

RED CEO responses: An optical issue that reflects on the stitching line

RED CEO, Jarred Land has joined the FB conversation and elaborated on that matter: “This most likely is not actually a sensor stitching issue… every VV sensor we have made has been stitched. It seems to be an optical issue with the adapters but that analysis is a bit premature, we are still exploring…The flare from the vary rare stray light at extreme angles bounces around the adapters sweeping across the sensor which highlights the split. You can do this on DSMC2 and other cameras without a mount. Most adapters don’t have any flare control so it’s where we are dialing in. In regard to the reason why the RED VV sensors are stitched, Jarred responded: “Most larger than full-frame sensors are stitched. It’s a manufacturing restriction and it’s usually never an issue…Great calibration fixes that for the most part except for super extreme instances where most of all this stuff happens”

The flare from the vary rare stray light at extreme angles bouncing around the adapters sweeping across the sensor which highlights the split.

Jarred Land – CEO at RED Digital Cinema

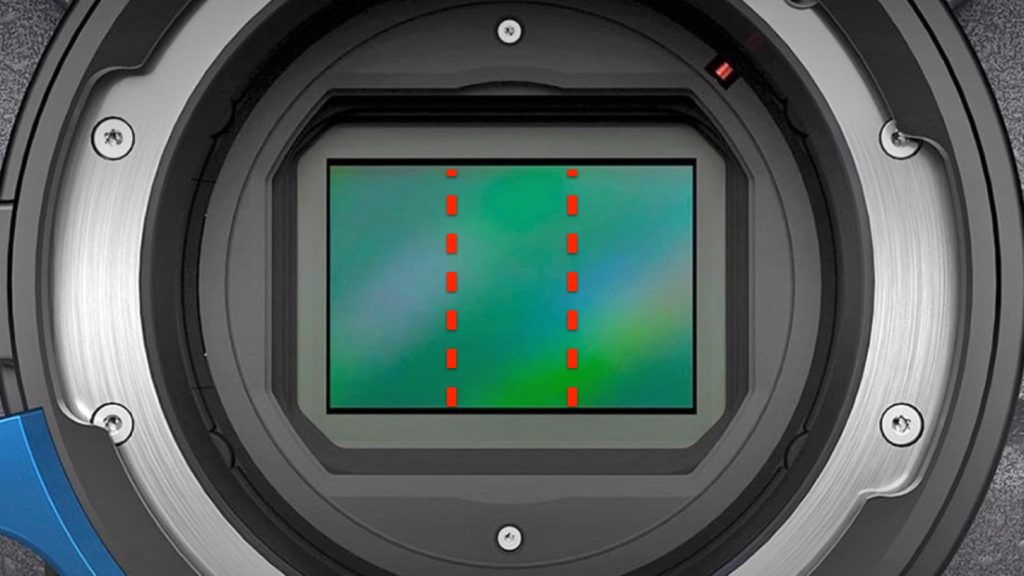

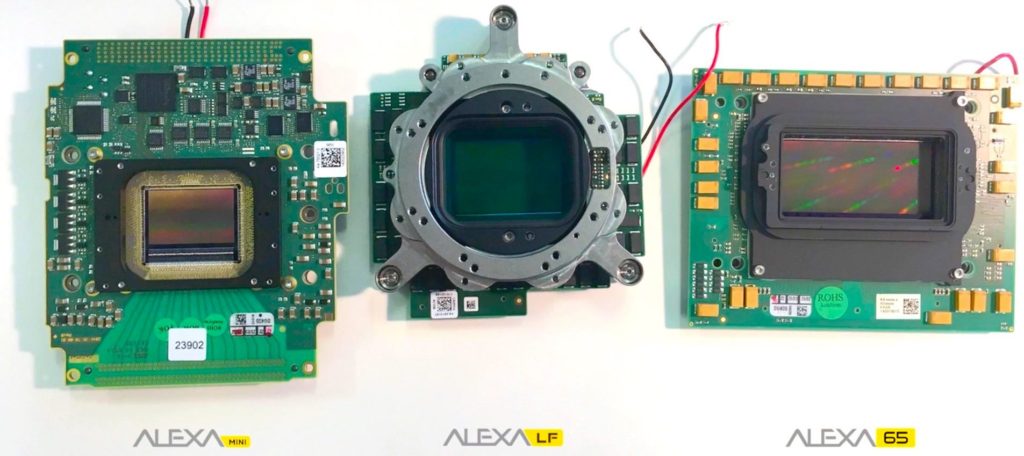

Stitching is a normal manufacturing process

The global name for the technique which allows large circuits to be made is called ‘stitching’. The accuracy of the process is such that the stitching lines are nearly undetectable. Stitching technology overcomes the exposure-field limitation by merging multiple design structures on the wafer to create a single CIS (CMOS Image Sensor). A high-precision alignment method allows these structures to slightly overlap, fusing them into a single integrated chip. The wafer is manufactured, and the chip is tested, sawed, and packaged as an integral unit. The stitched chip is for all practical purposes the same as a chip manufactured in the standard manner. Hence, stitching is a normal procedure for manufacturing large CMOS sensors. The large-format cameras by ARRI, contain stitched sensors as well (LF, Mini LF – two stitched sensors, 65- three stitched sensors).

ARRI cameras as a case study

As explained and known, ARRI stitches its large-format sensors. In fact, ARRI defines the ALEXA 65 sensor as ALEV III A3X (3 sensors stitched), and the ALEXA LF and Mini LF, as ALEV III A2X (2 sensors stitched). It’s mentioned clearly in the technical specifications of the sensors (Link to source).

The ALEXA LF sensor consists of a large sensor structure that is created by exposing two Super 35 sensor structures side by side onto a silicon wafer. This process is, somewhat misleadingly, called “stitching”. As is common with stitched large format sensors in our industry, in rare situations it is possible to notice the boundary between the left and right image halves.

ARRI

ARRI’s warning regarding artifacts derived from the split

It’s important to note that ARRI informs its users that artifacts may be occurred due to the stitched sensors. Here’s ARRI’s warning as stated from the ALEXA LF and Mini LF user manual: “Stitching with ALEXA LF – The ALEXA LF sensor consists of a large sensor structure that is created by exposing two Super 35 sensor structures side by side onto a silicon wafer. This process is, somewhat misleadingly, called “stitching”. As is common with stitched large format sensors in our industry, in rare situations it is possible to notice the boundary between the left and right image halves”. Hence, ARRI notifies its users regarding the mentioned artifacts. RED should do that as well.

I’ve not noticed it in our cameras unless something horrible has happened and the camera has to go to service, as I’ve never seen this in the field and I’ve only seen it once in the service department.

Art Adams: Cinema Lens Specialist at ARRI

Can you notice the split on ARRI cameras?

According to Art Adams, who is a cinema lens specialist at ARRI, you can notice the ‘stitching artifact’ when underexposing at the highest possible ISO, recording RAW, and then lifting that in post. “Although even then you might not see it on ours. Typically, if you see stitching on our cameras something has gone horribly wrong and it’s usually a service issue. I shot some footage at 3200 on a Mini LF last week without problems, although I didn’t underexpose and pull it up.” Adams stated.

What increases the chances of causing the sensor stitch to be visible?

Here’s a question asked in the CML forum: “What increases the chances of causing the sensor stitch to be visible? flare angle, focal length, aperture?” Art Adams answered: “Probably any situation where usable detail is buried in noise and you try to pull it up. I don’t think you can do much with a lens to bring it out—it’s more about a mismatch between what the two sides are doing, which is all about the electronics and most visible in the noise floor. As I said, though, I’ve not noticed it in our cameras unless something horrible has happened and the camera has to go to service, as I’ve never seen this in the field and I’ve only seen it once in the service department”. (Link to source).

Summary

Stitching a couple of sensors together to create one large sensor is a common technique. However, there’s a chance it will produce artifacts on the RAW footage showing the split, which is completely normal and can be removed/fixed in post. Although this shown split is considered a rare phenomenon that occurs under very specific shooting parameters, cinematographers should be advised. RED should mention this fact and ‘warning’ on its Monstro and V-Raptors user guides.

Product list

Here’re the products mentioned in the article, and the links to purchase them from authorized dealers.

- RED V-RAPTOR 8K VV DSMC3

I’ve never seen such an artefact on my Monstro. It’s probably (as Arri says) only seen when the camera has been damaged (mechanicall by cleaning the sensor…?) who knows. I sometimes push my material to 12800iso and it’s never been present.